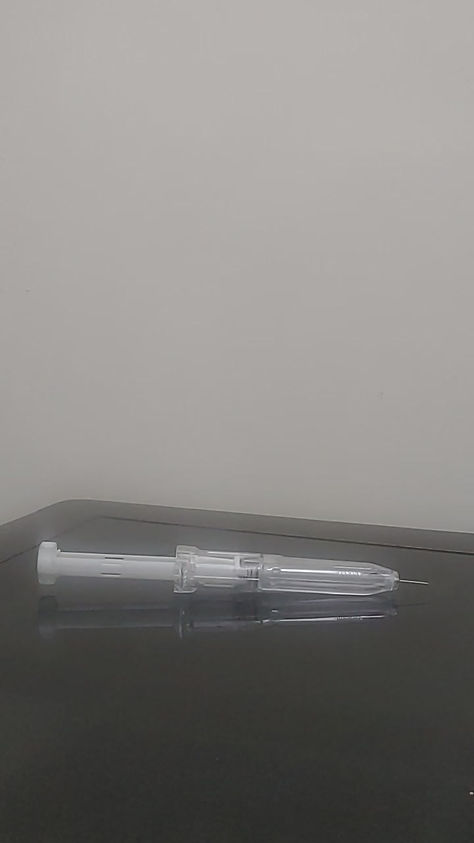

0.5mL Needle Safety Device

A passive (automatic) Needle Safety Device for high viscous depot-drugs. "A depot injection is a slow-release form of medication. The injection uses a liquid that releases the medication slowly, so it lasts a lot longer." They are very helpful in increasing medication adherance among patients who constantly forget to take their medicine.

This specific model is designed for Lanreotide depot drug. Lanreotide is given to patients with acromegaly. This injection is designed to be self-administered or given by a healthcare provider.

3D Printed working prototype using DLP, SLA and SLS 3D Printing for replicating Injection Molded plastic behaviour. (Transparent parts are DLP 3DP + lots of fine finishing + glossy lacquer)

Patients with acromegaly usually have very large hands as shown in the image, because of which the device had to be made a bit large in size (diameter) for it to be comfortable for the users. Also, since the device is designed for depot drugs which are mostly highly viscous the syringe internal diameter could not be higher than 3mm, otherwise the injection force would be uncomfortably higher (>8N). These are the two reasons behind having such a large device.

C

O

N

F

I

D

E

N

T

I

A

L

Personal Contribution: Co-Development (team of 2) of the mechanical delivery mechanism and Needle retraction mechanisim that does not violate any other drug delivery IP, Lead the Human Factors / Usability Engineering study (Work done for Mediscient Devices Pvt. Ltd.)

Disclosure: A device with similar user steps but completely different mechanism exists in the market, this is completely normal in drug delivery device sector.

User Steps:

The device has 5 step operation as shown in the slideshow.

At the end, the device gets locked in the needle-retracted position and it can't be pushed or pulled from that position. This makes the device disposal easy and ensures no needle-stick injuries occur.

Initial 3D Printed trial:

As it is seen in the video, I faced a lot of problems in getting the retraction to occur smoothly because of high frictional resin 3D printed parts and for final locking as well, I had to pull plunger assembly out to make it lock.

Working Mechanism

Final 3D Printed Prototype:

As it is seen in the video, prevously faced problems have been resolved. We spent a lot of time in prototyping the transparent outer body of this device as it has complex geometry on the inside.

Once the injection is complete, the needle retracts and the plunger can not be pushed or pulled anymore.

Even though the drug dosage using this device is only 0.5mL max, the reason behind having such a long device is the high viscous drug. It would need a significnty low syringe internal diameter to flow out with a feasible force.